Dark Star – Origins

Since I was small, I’ve been a tinkerer, fascinated by how things worked and fixing stuff if need be. I was born into a motorcycle-loving family and had my first dirt bike before I got a bicycle. The dirt bike had training wheels, of course. As my dad would work on his bikes, I would watch and, at one point, even use my plastic kids’ tools to do the same.

Early Years and Mechanical Fascination

I got to see some simple mods and how easily equipment could be upgraded. It just took some thought like a CR250 getting a disc brake conversion with some scrapped parts with just a small DIY bracket. These experiences changed how I looked at machinery, and I was hooked. By the time I was 8, I had rebuilt my first top end on one of my bikes.

From a young age I had a curiosity about machinery. I also had exposure to BB guns thanks to my uncle, who had one of the Crossman AR lookalikes. Shooting this, paired with the boyhood love of GI Joes, led me to love the AR-15, knowledge of Colt, and the usual enjoyment of firearms.

Expanding Interests: From Machinery to Firearms

In my teens, I transitioned from the Pumpmaster 760 and some other airgun models to a .22. Those eventually led to paintball, which fed my need for a higher pace of activity and skill. I continued tinkering, finally settling on a future career as an engineer. As I headed to college, I filled my classes with the available CAD, design, and CNC-based classes.

While in college, I worked in a garage as a mechanic while taking full-time classes. I also had the opportunity to intern as a production assistant at a window factory. I helped finalize and integrating an entirely new product line into production.

Educational and Early Career Path

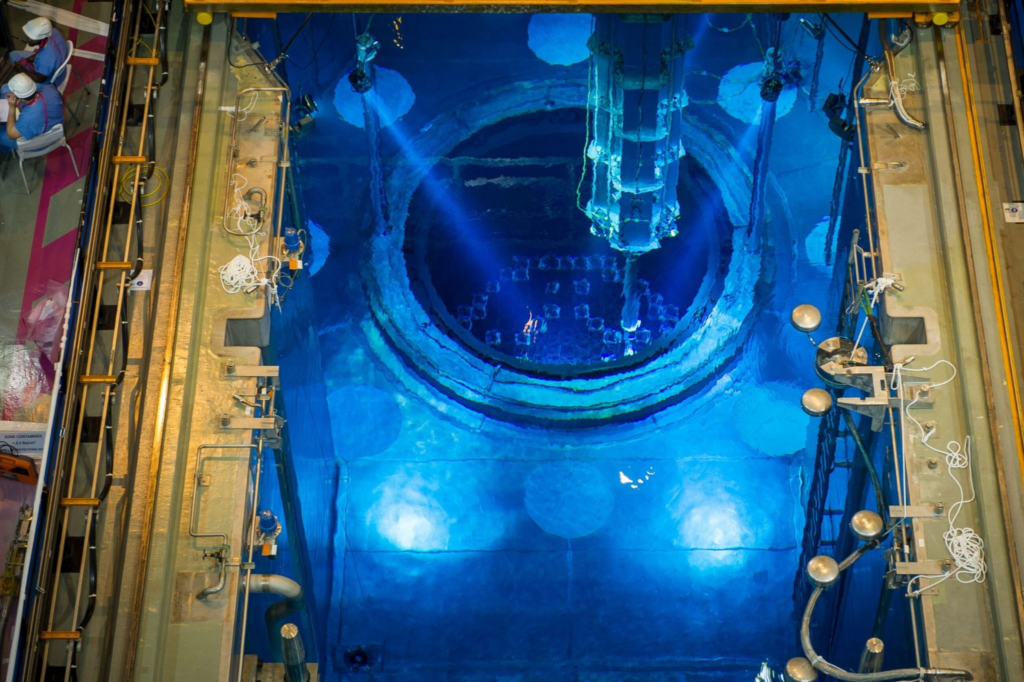

After graduating with two degrees in design and mechanical engineering, I went to my job of choice. That ended up being designing and analysis in the nuclear industry. I had the opportunity to engineer repairs and modifications to the operating nuclear power plants. I’d also work with adjacent nuclear locations to develop new waste treatment and disposal innovations.

At the time I worked in the industry, the New Nuclear Renaissance was happening. I was fortunate to help design some significant portions of the US and China-based AP1000 plants. How does this play into Dark Star? Overtime… Work was crazy, and the race to get things done had me at a professional salary, still entry-level, but we had so much work that overtime was common.

Pursuing a Passion in Firearms and Training

That overtime sparked the funds for ARs, handguns, and training. After blowing the first few adult paychecks on a mountain bike, guitar, and other odds and ends, I settled into some of the activities I’d wanted to do but hadn’t had the money for. With the AWB sunset and the 2008 crunch in high gear, I did what all engineers did and hyper-analyzed my way into an AR that was way more than I needed but was still awesome. I purchased a Noveske N4 with the rail installed. The retailer owner was a training junkie, and when I picked up my gun, he convinced me to try some training. It wasn’t that I thought I was good; the idea of general training wasn’t that popular at that time.

I knew Mas Ayoob but never thought about carbine classes or shooting competitions. After a free class from a local instructor who also happened to be in the nuclear industry, I learned a ton, and the improvement from zero to competency was addicting. I quickly signed up for my first paid class, Ken Hackathorns Advanced Pistol.

While I ramped up training, I also started the gear acquisition process. Once I settled on the then-new M&P line, I needed to get support gear to carry and shoot. Raven Concealment Systems was the de facto standard at the time, and if you carried a pistol, you had it in an RCS Phantom.

Unfortunately, their lead time back then was insane, somewhere between 18-24 weeks. That wait time was enough time for me to spend the money, wait, and then get impatient waiting and figure I could make something myself.

In a local shooting circle, I joined, one of the guys had been making Kydex holsters. Not able to leave well enough alone, I suggested changes and tweaks to his designs. He was nice enough to help me a bit, sorting some time and temperature settings, but his designs were fine. He patiently dealt with me for a bit, finally suggesting I make my own holster designs, which I did.

From 2008-2009, I did the usual tinkering and melting of plastic in the kitchen, honing in on some ideas that might be improvements to what was currently available. When my RCS Phantom arrived, I was ready to make a “real” holster. My first clone was 0.060″ Kydex and was usable. With the sample and first attempt, my #2 and #3 holsters were great and still functional today.

As I improved my designs, my local circle pushed me to make more for them and to sell to capitalize on the demand. I continued down this path because I didn’t want what was available then. What was on the market was great, but I wanted to add and remove to make the holsters just what I wanted them to be.

Founding Dark Star Gear

The first holster I officially sold online was a dark red Sig Mosquito OWB. This holster was an attempt to try my “final” ideas without having to tape up my carry gun or mess things up. In my show and tell online, someone asked to buy it. It was different from friends and locals, but this became the official start of our company.

With a push from friends, Dark Star Gear was born, and we started to sell our products on the forums. Why Dark Star? The name came from the Grateful Dead song “Dark Star,” a fantastic song that has evolved throughout their career and was often their vehicle for improv.

There’s a certain level of mystery with the name as well since it isn’t obviously a gun company name, and we wanted our customers to be able to wear our shirts without the Dynamic-Kinetic-Tactical-Systems obviousness.

The idea of dark stars, unseen and as of yet undiscovered, being the mysterious origin of the universe’s energy made the name even more applicable, as our holsters were not easily visible when concealed, but they contained the energy needed for self-defense.

After the name was set, we made a website and business cards and started the foray into social media in May of 2011, stepping out from forums a bit and seeing what we could do. While the company was starting, I was shooting IDPA every few weeks, along with NRA Highpower, periodically. I linked up with Todd Louis Green and his community, at this time very much on the fringe of the gun community.

Innovation and Expansion

We continued to analyze and try to improve the holster designs of the time, taking the Custom Carry Concepts designs and changing those designs to make a better holster. Our first AIWB was a pseudo adjustable belt wedge-based AIWB design with a leather backer and soft loops. Using this holster and still training excessively, we eventually shifted the company designs to focus more on AIWB sales, working to meet customer demand.

Our shift to AIWB coincided with the rise of Shivworks/Southnarc. The then face-blurred Craig Douglas had his forum, Total Protection interactive, which was a very synergistic place to Todd’s forum, Pistol-Forum.com. We were connected to the community of AIWB, “You’ll shoot your junk off holsters” and “karate on the gun range,” before it was more mainstream. First observing ECQC and then training it, we fleshed out concepts like belt flexibility through discussions about what worked and didn’t in the training world. Through the new skills and training environments, we worked to find new standards for holster durability and sustainability.

At one of Todd Green’s Aim Fast, Hit Fast classes, my brightly colored holster made reholstering easier, and color became another go-to design element. Intentionally breaking gear was also a thing. Be it belt loops or other things, we did our best to ensure things would last a reasonable amount of time. As time went on, mainstream acceptance of AIWB and the Shivworks curriculum began to influence gear more, and we had a few introductions of new ideas or modern manufactured versions of these ideas.

The tinkering didn’t end, as we continuously looked to improve designs. We used soft OWB loops to keep holsters narrow and prevent breakage. We watched the progress of brands like RCS, moving to injection molding and shifting from a wedge-based AIWB to a wing-based AIWB, serving more customers and reducing manufacturing times.

As AIWB became more normalized, our company was able to grow, supplying customers with what they wanted. We shifted to CAD-designed CNC molds and attachments like our injection molded wings, Dark and Light, creating a smoother and more comfortable holster for consumers.

Dark Star Gear is more than just a company; it’s an evolution of our consumers’ needs and our desire for continued improvement. We continue to work hard to define the problems actual users might encounter and work to find solutions that will work.